I. Ukucatshangelwa kokuklama nokukhetha

- Ukuhambisana Kwebanga Lokushisa

- Qinisekisa ukuthi izinga lokushisa lokusebenza le-NTC limboza indawo yesistimu ye-AC (isb, -20°C kuya ku-80°C) ukuze ugweme ukukhukhuleka kokusebenza noma ukulimala ngenxa yokweqa imikhawulo.

- Ukunemba kanye Nokulungiswa

- Khetha izinzwa ezinemba okuphezulu (isb, ±0.5°C noma okungcono) ukuze uthuthukise ukuzwela kokulawula izinga lokushisa. Ukulungiswa kufanele kufane nezidingo zesistimu (isb, 0.1°C).

- Ukuthuthukisa Isikhathi Sokuphendula

- Beka kuqala izinzwa ezinezikhathi ezishisayo eziphansi (isb, τ ≤10 amasekhondi) ukuze unike amandla impendulo esheshayo futhi uvimbele ukuhamba ngebhayisikili komminyanisi.

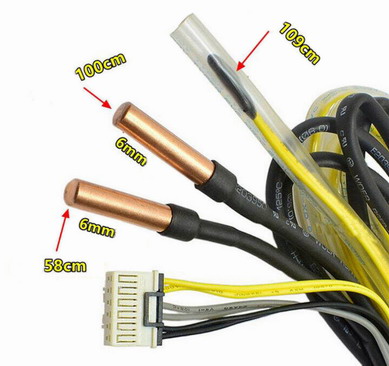

- Ukupakisha Nokuqina

- Sebenzisa i-epoxy resin noma i-glass encapsulation ukuze umelane nomswakama, ukujiya, nokugqwala kwamakhemikhali. Izinzwa zeyunithi yangaphandle kufanele zihlangabezane nesilinganiso se-IP67.

II. Indawo yokufaka kanye neMechanical Design

- Ukukhetha Indawo

- Ukuqapha kwe-Evaporator/Condenser:Namathisela ngqo endaweni yamakhoyili, ugweme ukugeleza komoya okuqondile (isb., >5 cm ukusuka ezintubeni).

- Buyisela Izinga Lokushisa Lomoya:Faka phakathi nendawo yamapayipi abuyayo, kude nemithombo yokushisisa/yokupholisa.

- I-Thermal Coupling

- Vikela izinzwa ngamafutha ashisayo noma izinsimbi zensimbi ukuze unciphise ukumelana nokushisa phakathi kwenzwa nendawo eqondiwe.

- Ukunciphisa Ukuphazamiseka Kokugeleza Komoya

- Engeza izihlangu zokugeleza komoya noma sebenzisa ama-probe anezivikelo ukuze unciphise imiphumela yesivinini somoya (okubalulekile kumasistimu okupholisa umoya).

III. Izinkombandlela Zokuklama Kwesekethe

- Amapharamitha we-Voltage Divider

- Fanisa izinqamuleli ezidonsela phezulu nokumelana okulinganiselwe kwe-NTC (isb, 10kΩ ku-25°C) ukuze kuqinisekiswe ukuthi i-voltage yokufaka ye-ADC iwela phakathi kwebanga elisebenzayo (isb, 1V–3V).

- Ukwenziwa komugqa

- Sebenzisa isibalo se-Steinhart-Hart noma amathebula okubheka kancane ukuze unxephezele ngokungaqondile futhi uthuthukise ukunemba.

- I-Noise Immunity

- Sebenzisa izintambo ezisontekile/ezivikelekile, umzila osuka emithonjeni yomsindo ophezulu (isb., ama-compressor), futhi wengeze izihlungi ze-RC zephasi eliphansi (isb, 10kΩ + 0.1μF).

- Ukuvikelwa Komswakama

- Vala izinzwa zangaphandle ngezinhlanganisela zokubumba futhi usebenzise izixhumi ezingangeni manzi (isb., amapulagi endiza ye-M12).

- Ukumelana Nokudlidliza

- Vikela izinzwa ngezikhwezi eziguquguqukayo (isb., amaphedi e-silicone) ukuze uvimbele izinkinga zokuxhumana kusukela ekudlidlizeni kwe-compressor.

- Ukuvimbela Uthuli

- Hlanza njalo izinzwa noma sebenzisa amakhava okuvikela akhiphekayo (isb., anezikhala zensimbi).

V. Ukulinganiswa Nokugcinwa

- I-Multi-Point Calibration

- Linganisa emazingeni okushisa abalulekile (isb., 0°C ingxube yamanzi eqhwa, 25°C igumbi elishisayo, 50°C okugeza kawoyela) ukuze ubhekane nokuhluka kwenqwaba.

- Ukuhlola Ukuzinza Kwesikhathi Eside

- Yenza ukulinganisa kwenkambu njalo eminyakeni emi-2 ukuze uqinisekise ukukhukhuleka (isb, ukukhukhuleka konyaka ≤0.1°C).

- I-Fault Diagnostics

- Sebenzisa ukutholwa komjikelezo ovulekile/omfishane kanye nezixwayiso zokucupha (isb, ikhodi yephutha ye-E1) ngokungahambi kahle.

VI. Ukuphepha Nokuhambisana

- Izitifiketi

- Qinisekisa ukuthobelana namazinga e-UL, CE, kanye ne-RoHS ngokuphepha nezidingo zemvelo.

- Ukuhlolwa kwe-Insulation

- Qinisekisa ukuthi ikhebula likwazi ukumelana no-1500V AC iminithi elingu-1 ukuze uvimbele izingozi zokuwohloka.

Izinkinga Ezivamile Nezixazululo

- Inkinga:Ukusabela kwenzwa ebambezelekile okubangela ukujikeleza kwe-compressor.

Isixazululo:Sebenzisa ama-probes amancane (okuphansi τ) noma ulungiselele ama-algorithms okulawula i-PID. - Inkinga:Ukwehluleka ukuthintana okubangelwa ukujiya.

Isixazululo:Beka kabusha izinzwa kude nezindawo zokufingqa noma sebenzisa okokunamathela kwe-hydrophobic.

Ngokubhekana nalezi zici, izinzwa ze-NTC zingaqinisekisa ukusebenza okuthembekile ezinhlelweni ze-AC, ukuthuthukisa ukusebenza kahle kwamandla (EER) nokwelula isikhathi sokuphila kwemishini.

Isikhathi sokuthumela: Apr-25-2025